A selection of completed projects across railroad, fuel storage, manufacturing, and industrial automation.

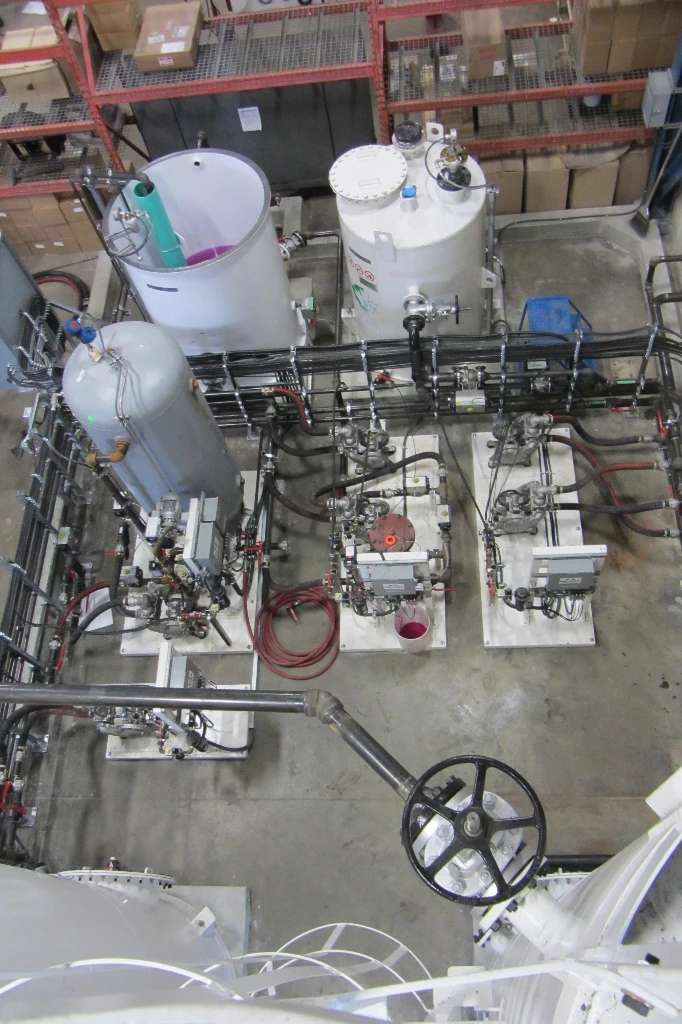

An automated dust suppression system designed to apply adhesive spray to coal car loads during transit. The system prevents coal dust from becoming airborne, addressing environmental and safety regulations. The design included spray nozzle arrays, pump and distribution systems, PLC-controlled sequencing tied to train movement detection, and integration with existing site infrastructure. The system was designed for unattended operation in harsh outdoor conditions.

BNSF Re-Spray Facility

Water Spray Test

This facility was designed for servicing locomotive lubricants and cooling fluids. It included a sub-floor inspection pit, a miniature-scale dissolved air flotation (DAF) wastewater treatment package, waste oil disposal systems, vehicle wash facilities, and exhaust run-up extraction fans. The project required coordination of multiple trades including welding, electrical, plumbing, HVAC, and concrete work, all delivered on a tight schedule.

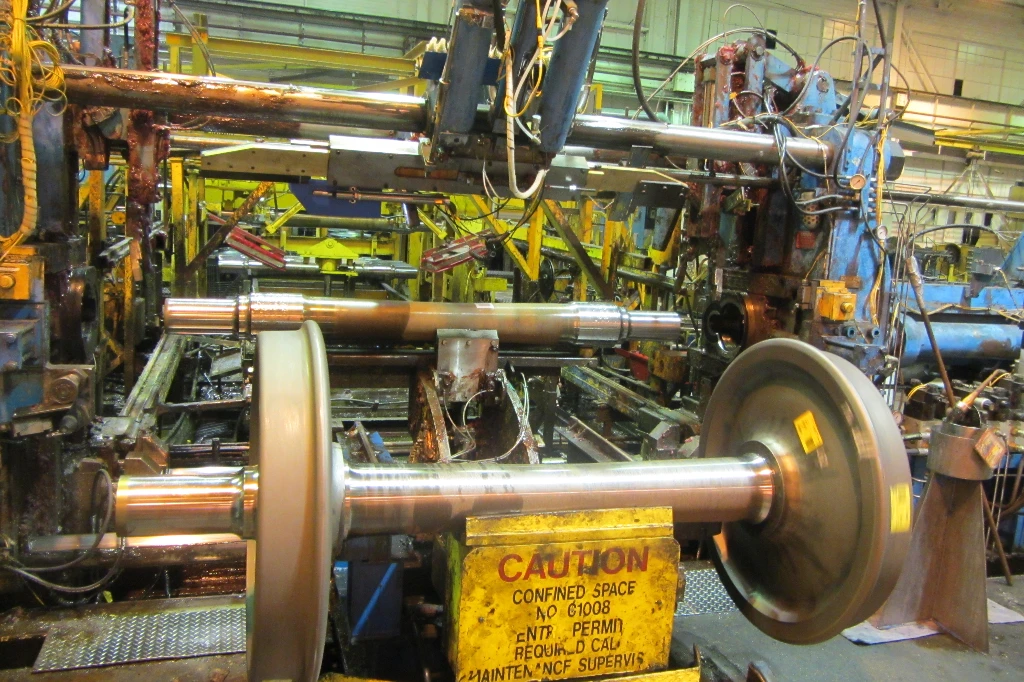

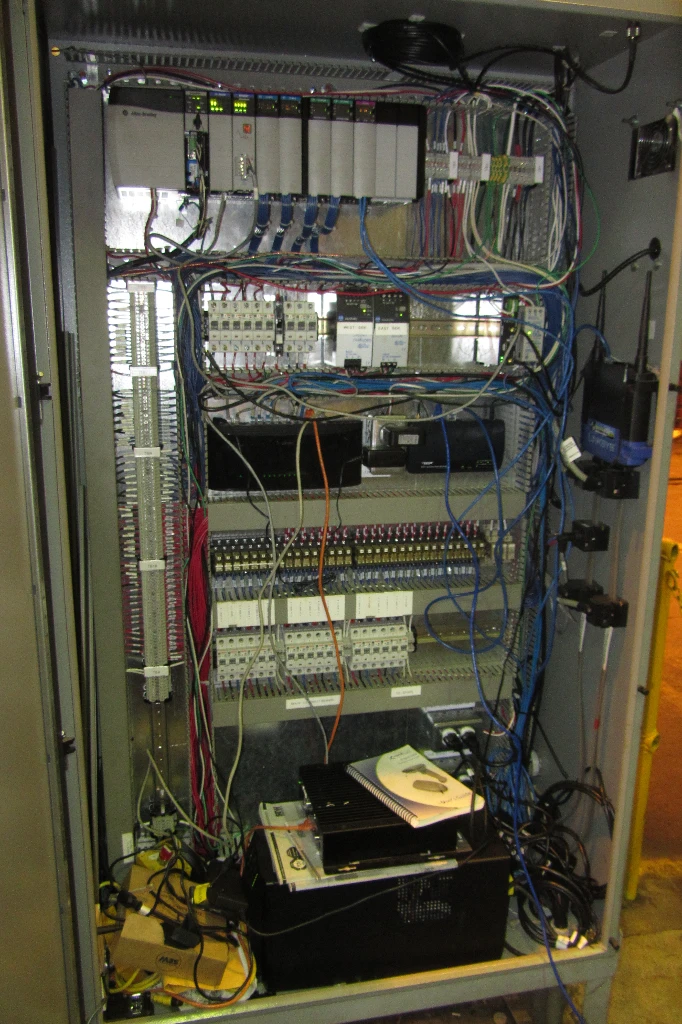

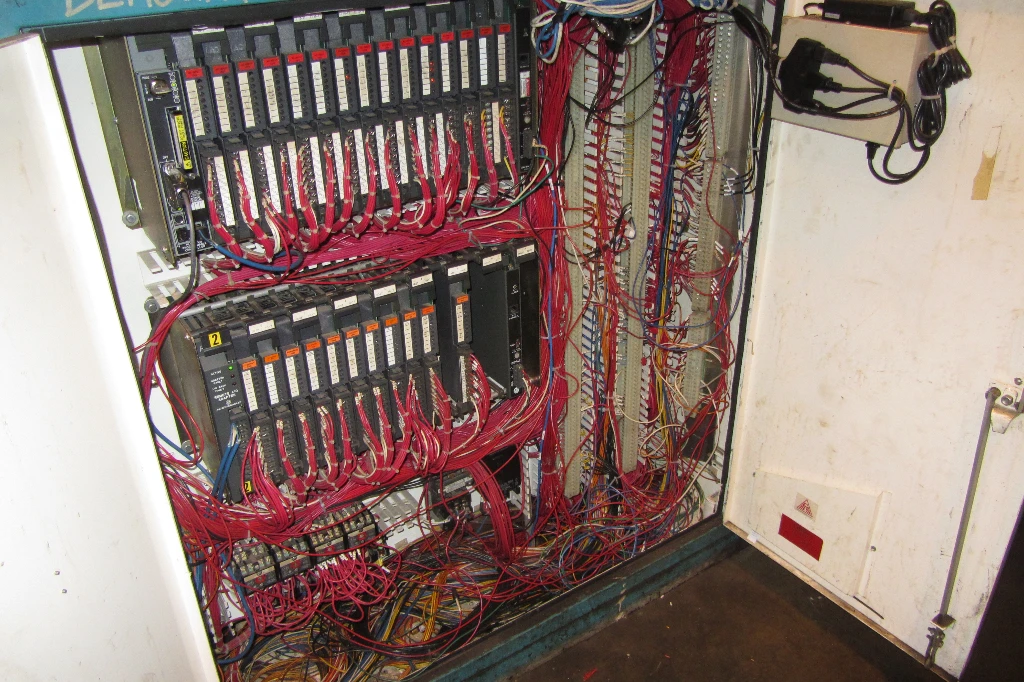

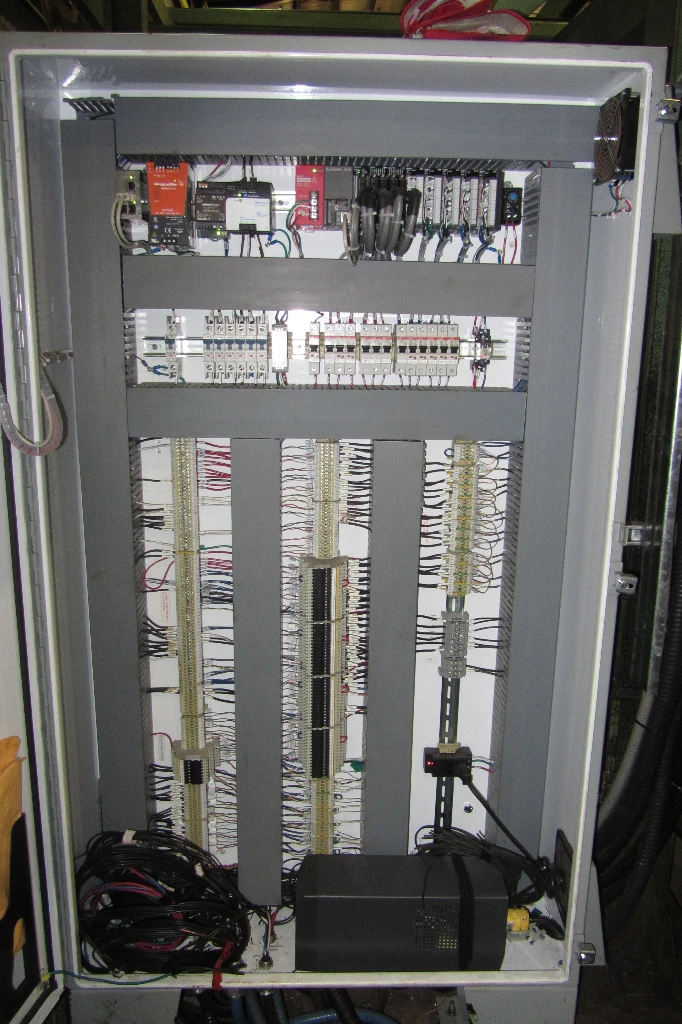

A series of projects delivering heavy equipment for the remanufacturing of railroad wheelsets. Scope included wheelset dismount presses, axle wash stations, material handling systems, CNC lathes for wheel profiling, and remount presses. A key component was upgrading legacy relay logic to modern PLC control with custom HMI panels for operators. Equipment was installed at multiple railroad maintenance facilities across Canada and the USA.

Demount Railroad Wheelsets

Railroad Axle Wash

Wheelset Material Handling

Replacement of existing fuel storage infrastructure with new 1-million-litre diesel tanks designed and inspected to API 650. The project included tank demolition, site preparation, new tank erection, cathodic protection systems, secondary containment, and integration with the existing refueling distribution network. A critical requirement was maintaining full site operations throughout construction — no shutdown was permitted.

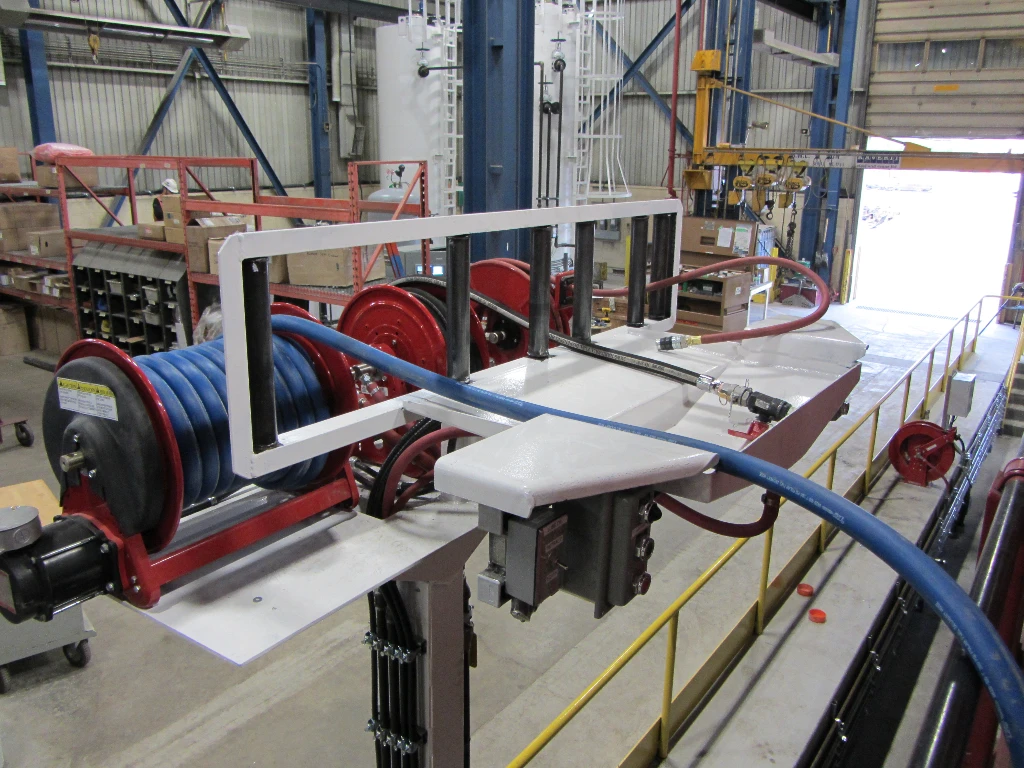

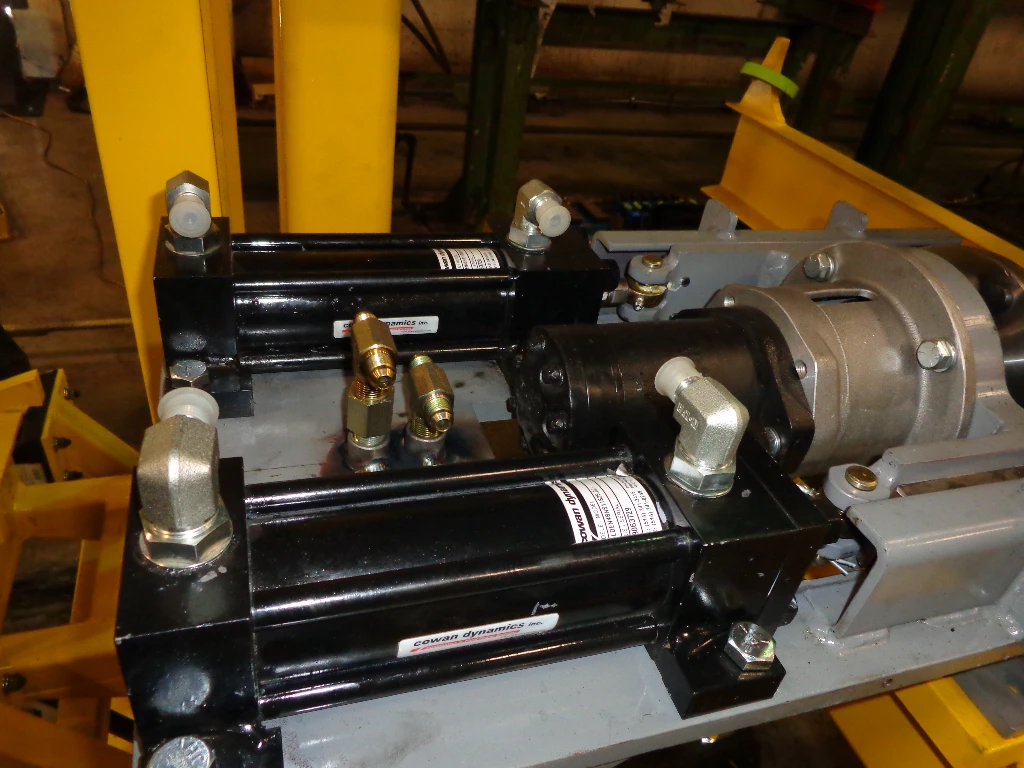

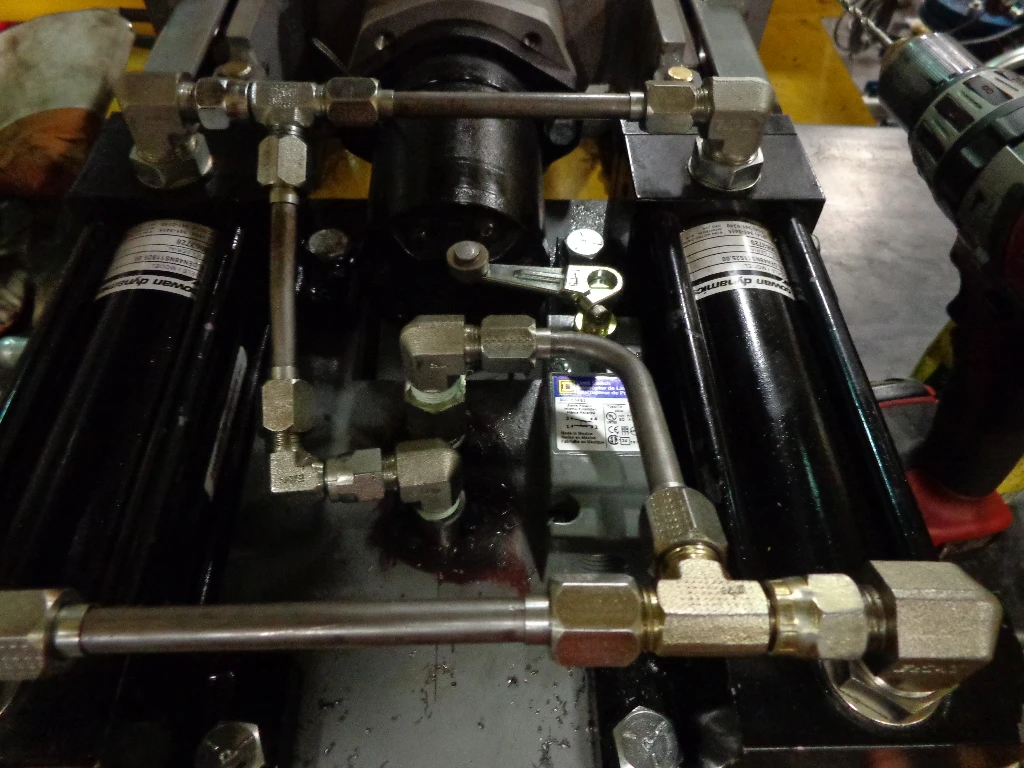

Hydraulic drop table systems designed and installed for railroad wheelset servicing. These tables allow maintenance crews to lower a railcar's trucks and wheelsets out from beneath the car for inspection, repair, or replacement. Each installation was custom-designed for the specific facility layout and load requirements, incorporating hydraulic power units, PLC-based sequencing, and operator safety interlocks. Systems were installed at multiple railroad maintenance facilities across Western Canada.

Wheelset Drop Table — Commissioning

A cross-section of automation and software work spanning multiple industries and platforms. Our controls experience includes PLC programming across Rockwell (Allen-Bradley), Mitsubishi, Siemens, Omron, and Phoenix Contact platforms. We design HMI touchscreen interfaces for operators and maintenance personnel, SCADA systems for monitoring and reporting, and custom desktop software for production support. Beyond industrial controls, we develop in C++, Python, and VB/C#.NET, and have worked with computer vision (OpenCV, CUDA) and embedded systems (NVIDIA Jetson).

We are always interested in hearing about new challenges.